MOLD POLISHING AND

FINISHING

We understand what it takes to stay ahead in our industry which is why we are continually evolving to create new and better ways to meet your needs and challenges. Our skilled technicians use the best equipment from Diprofil, understand your time constraints and work the hours necessary to get your project done the right way, on time, and on budget. We take pride in our work and assure you that quality will never be sacrificed. Alliance means a partnership with our customers built on hard work, dedication and a commitment to excellence.

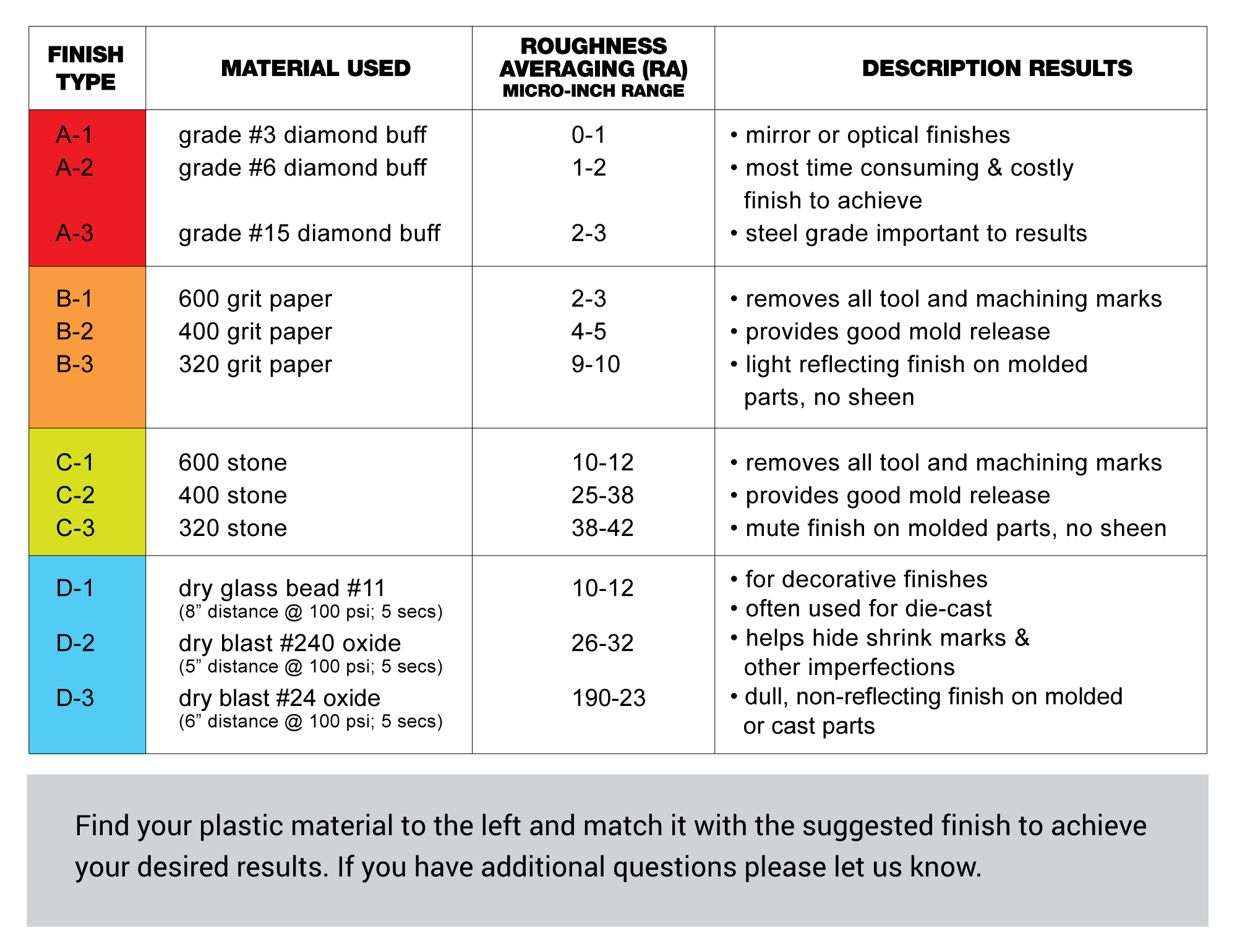

Professionally finished products are our only business. At Alliance we understand your polishing needs and work closely with you to assure not only a quality job but also a job done to SPI-SPE standards. Many products you use and see daily from Fortune 500 companies, have had molds polished to the highest standards by our craftsmen such as hardware, housewares, home accessories, automotive, medical devices and more. You won’t see our name on it, but you will recognize our quality.

SPECIALIZED SERVICES:

ULTRA SONIC POLISHING

OPTICAL FINISHING

ALUMINUM FINISHING

WELD BLENDING

VAPOR HONING

SAND BLASTING

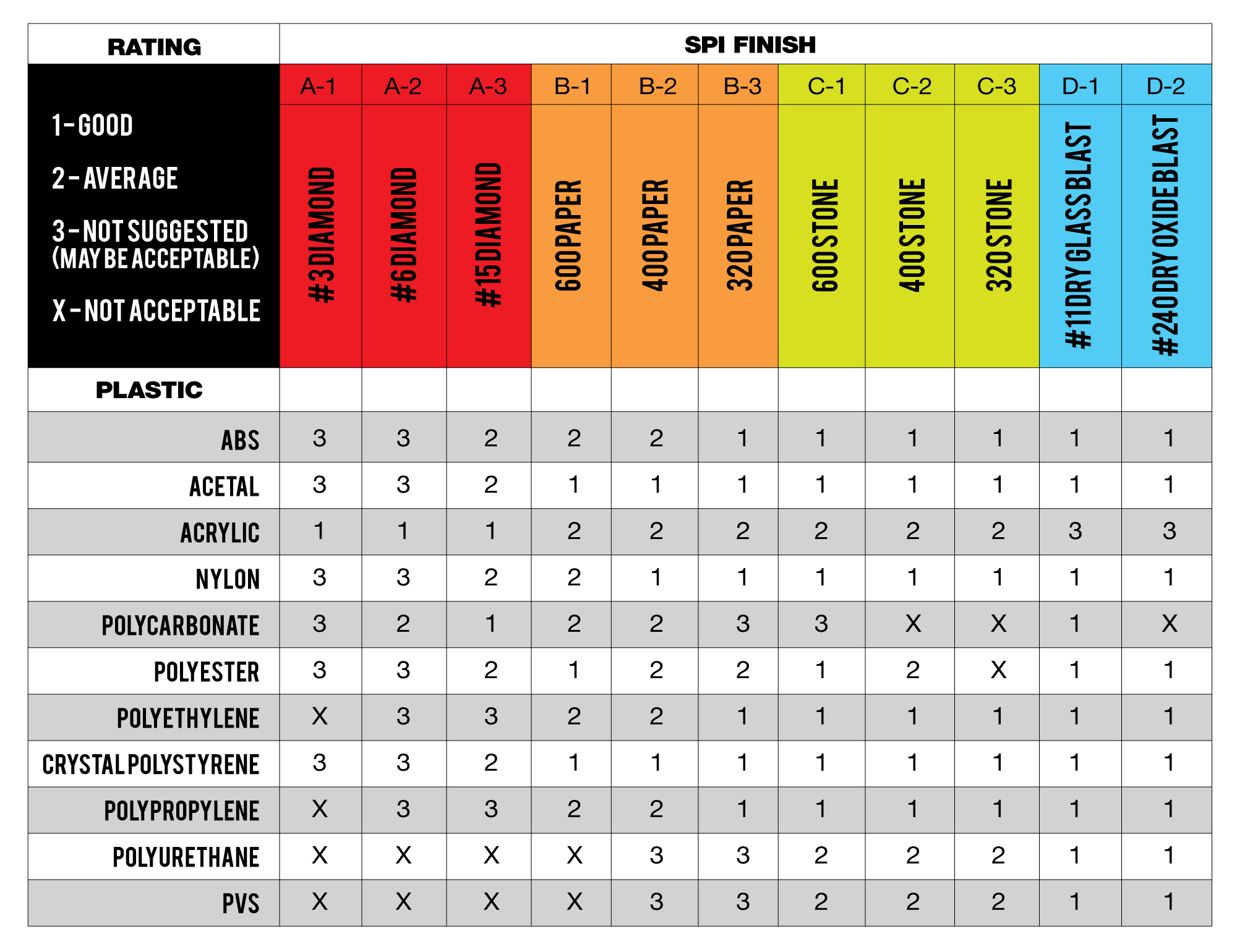

CHOOSING THE RIGHT FINISH

Different plastic products and materials call for specific finishes for the best possible results. Lucky for you, we have been around long enough to understand what works and more importantly what doesn’t. Our team will work with you to make sure that you have the right finish ensuring your parts are done right the first time.

We want to work with you.

We bring over 40 years of knowledge and experience to the table. We want to work with you to find the right solutions to your molding challenges. Send us an email and we will get back to you within 24 business hours.

Alliance Service Quote

Alliance Specialties and Laser Sales

Alliance Laser Sales California

MACHINE SALES

LASER WELDING MACHINES

- VISION Unixx III

- VISION MobileFlexx

- VISION MobileFlexx ToolRoom

- VISION Ultra Flexx

- VISION Ergo

- VISION T-Base

- VISION Small Chamber

- ALLIANCE ID1-Fiber Laser

LASER ENGRAVING MACHINES

MOLD SERVICES

LASER WELDING MACHINES

STRATEGIC PARTNER