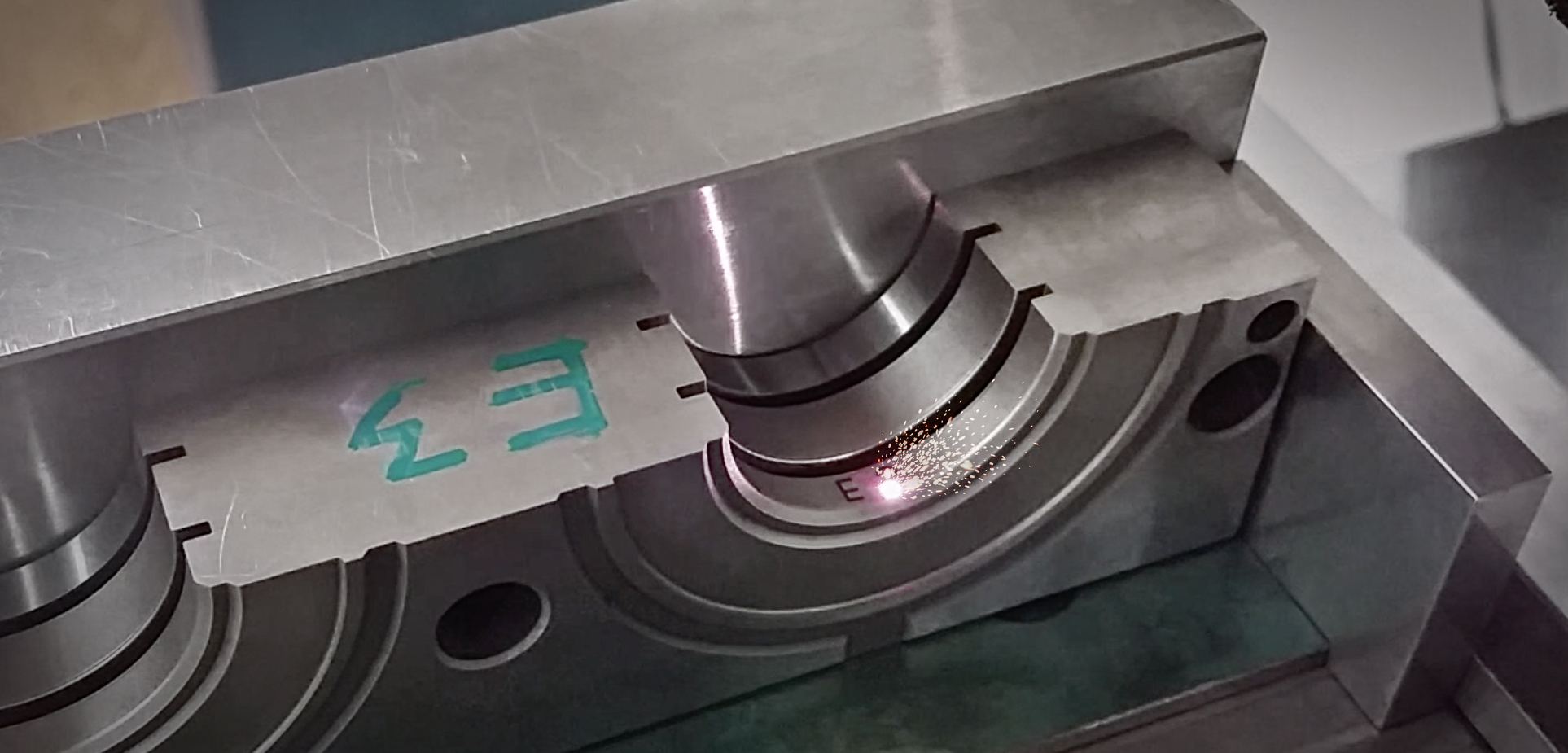

LASER ENGRAVING AND MARKING

Alliance laser engraving allows for the most efficient and accurate method of marking available. Company logos, part numbers, mold venting or any other need is now possible with less downtime. Even better, we can teach you how to do it when you purchase your own Alliance laser engraving system.

Unlike traditional methods of engraving the cutting tool is a non-contact, highly focused beam of light which eliminates a portion of metal producing the mark. The fact that laser engraving is non-contact process is a huge benefit as it reduces the risk of overall mold damage and subsequent part deformation. Because the laser itself does not wear through repeated use, it continues to produce a highly accurate, repeatable engraving every time resulting in absolute consistency across multiple parts in every application.

This level of identical repeatability in traditional methods such as stamping and mechanical engraving is near impossible to achieve for a number of reasons. Another key advantage is the ability to engrave complex geometries and difficult to reach areas by manipulating the laser angle resulting in greater precision. Laser engraving is environmentally safe as the laser produces no chemical or toxic bi-products such as with acid etching. No special tooling is required, and the resulting mark is permanent, clean and precise.

MATERIALS AND SIZE CAPACITIES

We can mark or engrave most ferrous materials such as: Moldmax, Moldstar, SS, Carbide, and any soft or hard tool steels. We can also remove surface materials such as powder coating, anodizing, paint and surface rust. Engraved material sizes can go from .030” pins up to cavity blocks weighing thousands of pounds. Diameters are limited to approximately 6” and 40 lbs, although larger can be managed manually.

CHARACTER AND LOGO SIZING

We are able to get clear character markings down to .018” and up to a 6”x6” window that can be engraved all in one pass. For markings larger than 6”x6” we can break the engraving into sections and use multiple applications to achieve desired results. We also have 4th axis capabilities for doing radial marking on the heel of KO pins or gate inserts for example. Engraving depths can range from a .0001” surface mark to a .030” deep engraving.

QUALITY ASSURANCE

We take pride in our accuracy and tolerance holding abilities. We are able to hold depth and overall size tolerances to +/-.001 to tighter in most applications. We have digital depth gages, Mitutoyo tool maker’s microscope, optical comparator, and a Micro-Vu comparator along with most standard machine shop tools. Our laser engraving machines are equipped with digital read outs as well as HD Digital monitors for precise application.

We understand that this is a fast paced industry which is why we strive for same day turnarounds on most projects. Typical job turnaround times are 1-2 business days.

INTERESTED IN A LASER ENGRAVER?

LOWER ELECTRICAL CONSUMPTION

Because of the 100% solid state design our laser boasts an electrical efficiency up to 15X more efficient than older lamp pump systems which translates into significant cost savings for the user.

MAINTENANCE FREE

No lamp, mirrors or other expensive consumables to replace. This can represent a significant cost savings over the lifetime of a the typical laser engraving system.

AIR COOLED

Highly efficient design allows for a laser which is air cooled. No requirement for an external water cooling system.

SUPERIOR BEAM QUALITY

State of the art laser technology allows for a beam quality to which surpasses that of conventional lamp and diode pumped laser engravers. This translates into a highly efficient tool for all your engraving and marking applications.

SMALL SPOT SIZE

The small spot size of the Alliance NGRV1 gives the user the ability to set new standards for minimal readable characters and graphic reproductions.

We want to work with you.

We bring over 40 years of knowledge and experience to the table. We want to work with you to find the right solutions to your molding challenges. Send us an email and we will get back to you within 24 business hours.

Alliance Service Quote

Alliance Specialties and Laser Sales

Alliance Laser Sales California

MACHINE SALES

LASER WELDING MACHINES

- VISION Unixx III

- VISION MobileFlexx

- VISION MobileFlexx ToolRoom

- VISION Ultra Flexx

- VISION Ergo

- VISION T-Base

- VISION Small Chamber

- ALLIANCE ID1-Fiber Laser

LASER ENGRAVING MACHINES

MOLD SERVICES

LASER WELDING MACHINES

STRATEGIC PARTNER