Our laser welding department is leading the industry in services provided. As one of the earliest pioneers of the laser welding process, we know all of the ins and outs of what works and more importantly, what doesn’t. Using state of the art machinery paired with the ability to provide complete repair and finishing services on your parts, it is no surprise that Alliance is the premier choice when it comes to laser welding and repair.

With over 40,000 laser welding jobs in the tool and die field, as well as countless other industries served; Alliance Laser Sales confidently offers exceptional service, high quality, and extraordinary turnaround times.

We can laser weld tool steels, stainless steels, powdered metals, copper alloys and aluminum with as little as .003 wire. This allows us to achieve extremely small welds that in many cases can be hand worked back in order to avoid machining when needed.

Sharpen parting lines, repair shut-offs, engineering changes, water leaks, EDM arcing, broken cutters, cutter gouges, and engraving changes are just some of the reasons you may need to partner with Alliance for your welding needs.

We are not just the number one service center in the country, we are also a knowledgeable laser welding machine manufacturer and sales center. When it comes to laser welding, we have you covered.

%

PRODUCTIVITY

%

ENERGY EFFICIENT

%

HEAT STRESS

In difference to all other technologies of welding or soldering, the laser brings the necessary energy for the melting of the metal within some 1/1000 sec (ms). Due to the short time even at the power up to 12KW there is no strong heating. The melting process is so short that the average power is very low (60-200W only). The duration of the pulse in comparison with the relax time is very large. Even at high frequency of pulse repetition rate the relax time is very large. There is no other technology that offers such low heating in the welding process.

Because of this low heat the following advantages are achieved; Low deformity and little to no heat affected zone (HAZ) , minimal to no sink and far less cracking on sensitive materials. With Laser Welding you also have the ability to weld in places where the material is very thin, as well as the ability to weld within assembly, even if it is near a very heat sensitive area. Now you can easily weld materials with totally different thermal expansion levels. Because of the small deposition of welding material there is less machining, sometimes the parts can simply be hand worked or fit by a tool maker with no machining at all. All of this without having to preheat the materials.

2) Extremely Fine Welding: Due to the combination of a very fine laser beam with the microscope you have normal line for welding in the range from 0.2 to 1mm. In special cases you can achieve spots down to 50um.

3) Compatibility of Materials. Due to the fact that Laser Welding does not use an electrode, there are no impurities being introduced to the metal structure. On the other hand, you can use special wire to weld materials that normally are not possible to weld together.

4) Perfect Inert Gas Protection: Due to the low heating there exists no turbulence that destroys the protective gas atmosphere. The results are a really clean welding zone.

5) Ability To Weld Difficult Areas: Laser beams will always shoot straight and have zero concern for arcing. Magnetic fields do not affect the welding process. Tight, deep areas are possible and actually easy to access and work on. (if you can see it through the microscope and get protective gas to the area, you can weld it)

TYPICAL APPLICATIONS

- Parting line repair

- Gate and gate seal repair

- Shut-off repair

- Engineering changes

- Texture repair

- Tooling refurbishing

- Water leaks

SERVICE CAPABILITIES

- Job size from .1-10,000 lbs

- Tool steels

- Stainless materials

- Copper alloys

- Powdered metals

- Laser sintered materials

- Titanium

- Aluminum

IN-HOUSE MACHINE LIST

- (6) Laser welding machines | 120 – 450w

- (2) Tig welders | AC-DC

- (3) Laser engraving machines

TURNAROUND TIMES

- Standard turnaround of 48 hours

- Emergency while you wait service

- Same day turnarounds when feasible on items shipped in UPS, FedEx, etc.

- Expedited turnarounds on large projects

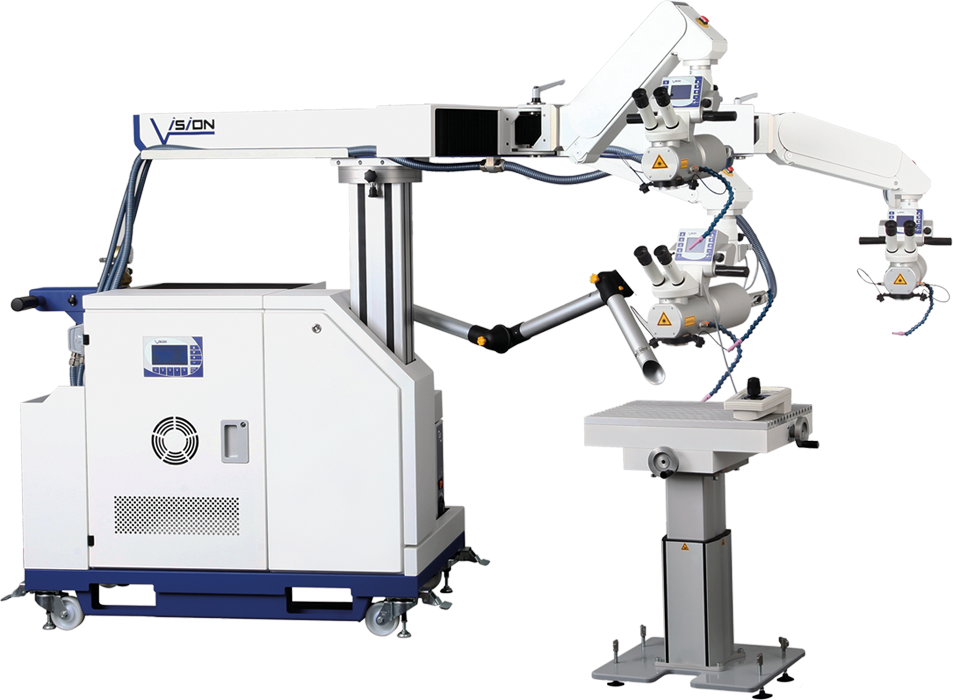

BUY A LASER WELDING

MACHINE

VISION MOBILEFLEXX TOOL ROOM:

We want to work with you.

We bring over 40 years of knowledge and experience to the table. We want to work with you to find the right solutions to your molding challenges. Send us an email and we will get back to you within 24 business hours.

Alliance Service Quote

Alliance Specialties and Laser Sales

Alliance Laser Sales California

MACHINE SALES

LASER WELDING MACHINES

- VISION Unixx III

- VISION MobileFlexx

- VISION MobileFlexx ToolRoom

- VISION Ultra Flexx

- VISION Ergo

- VISION T-Base

- VISION Small Chamber

- ALLIANCE ID1-Fiber Laser

LASER ENGRAVING MACHINES

MOLD SERVICES

LASER WELDING MACHINES

STRATEGIC PARTNER