Alliance Specialties and Laser Sales has a goal to make a difference for its customers through gratitude, relationships, integrity and tenacity. We are your home for American made laser welding and engraving solutions. We are mold builders who don’t build molds. Our expertise is complete injection mold finishing and maintenance needs, specializing in polishing, laser welding, engraving, mold maintenance and hot runner manifold repair, so that you don’t have to.

LASER SALES

LASER WELDING

LASER ENGRAVING

HOT RUNNER CLEANING

MOLD POLISHING

MOLD MAINTENANCE

- Stability 95%

- Ease Of Use 95%

- Versatility 100%

- Stability 100%

- Ease Of Use 95%

- Versatility 95%

- Stability 85%

- Ease Of Use 95%

- Versatility 97%

- Stability 85%

- Ease Of Use 95%

- Versatility 99%

- Stability 80%

- Ease Of Use 90%

- Versatility 100%

- Stability 100%

- Ease Of Use 90%

- Versatility 80%

- Stability 100%

- Ease Of Use 100%

- Versatility 85%

- Stability 100%

- Ease Of Use 95%

- Versatility 40%

- Stability 95%

- Ease Of Use 90%

- Versatility 100%

CUSTOMER TESTIMONIALS:

We used to job out about $200,000 of welding every year. I was concerned that because only 10% of that was laser welding buying a laser welder would not pay for itself. I was wrong. We are able to laser weld much larger areas than I thought we could in very efficient time. I'd say we now laser weld about 75% of our welding needs. The machine is very dependable, and when we do need service for something Alliance has always responded immediately. I can't imagine my business without our Alliance Laser.

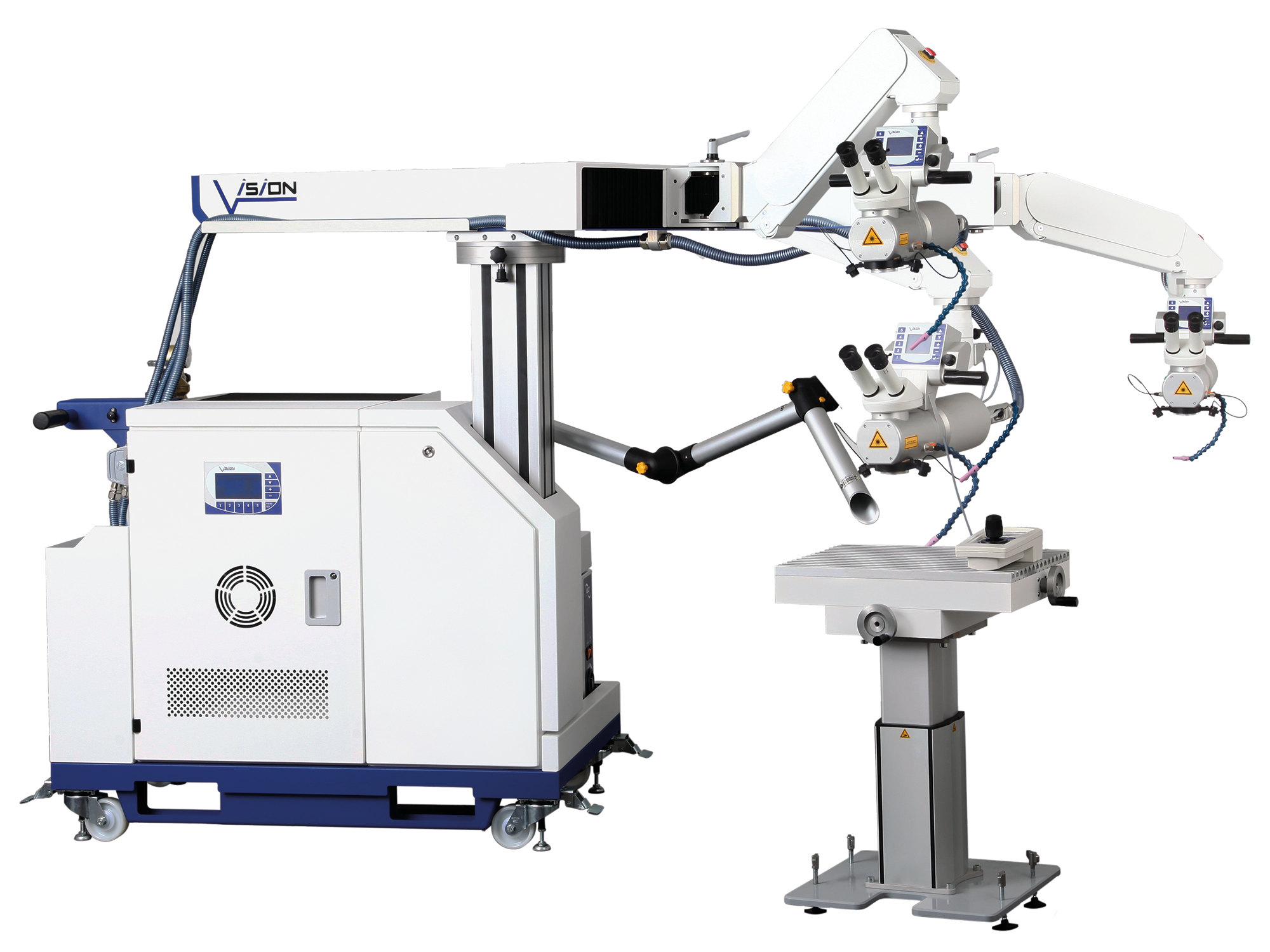

As a recent Lead Time Award winner, Industrial Molds Group requires the ability to complete engineering changes and repairs on the fly in the fastest time possible. It is for these reasons, as well as the quick learning curve, extreme ease of use and unmatched service and support from Alliance that we selected the Vision Unixx Laser Welding Station for our shop. Since installation, we immediately noticed huge improvements in timing, production and the bottom line.

When looking for a proven partner specializing in laser welding, mold maintenance and repair, ToolingDocs turned to Alliance for all of our needs. We are the only company offering the Vision Unixx Laser System for our clients to learn on in a real world environment. This machine has made a world of difference to our classes and seminars.

This business and this industry is challenging enough as is. I’ve owned 4 different lasers. I’ve experienced the challenges with other lasers. The ease of use, dependability, service and support on the Vision Lasers sold by Alliance Laser Sales differentiates them and their lasers from the others in the market. It’s the right tool for the job with the maximum uptime and the minimum drama allowing me to focus on my other challenges because laser welding isn’t one of them.

We want to help.

We can help you find the solution that you need. Better yet if you don't see a machine that meets your specific needs we would love to talk with you about creating exactly what it is you need. Give Alliance Laser the chance to be your partner.

Laser Welding Quote Request

Alliance Specialties and Laser Sales

Alliance Laser Sales California

MACHINE SALES

LASER WELDING MACHINES

- VISION Unixx III

- VISION MobileFlexx

- VISION MobileFlexx ToolRoom

- VISION Ultra Flexx

- VISION Ergo

- VISION T-Base

- VISION Small Chamber

- ALLIANCE ID1-Fiber Laser

LASER ENGRAVING MACHINES

MOLD SERVICES

LASER WELDING MACHINES

STRATEGIC PARTNER